The brief Introduction of melt blown fabric

Melt blown fabric, also called melt blown non-woven fabric, is the core material with filtering function in the mask making industry. The main raw material of melt blown fabric is polypropylene, which can achieve 80% of the filtering effect.

The melt blown fabric production factory

The melt blown fabric production factory

The melt blown fabric has good filterability, shielding, heat insulation and oil absorption, because of its many voids, fluffy structure, good fold resistance and other characteristics.

The production principle of melt blown fabric

The production principle of melt blown fabric is similar to that of marshmallow. First, the high-melt fiber material is melted by the hot air flow of high negative pressure, and then sprayed from the spinning micropores, and drawn into ultrafine fibers with a diameter of 0.3-7 microns. Under the guidance of the airflow, the ultrafine fibers are evenly spread on the collection device, and the residual heat will bond ultrafine fibers into net. However, the melt blown fabric bonded by the high-melt spinneret has only 30% filtering effect. If you want to improve the filtering effect, you need another operation-electret treatment.

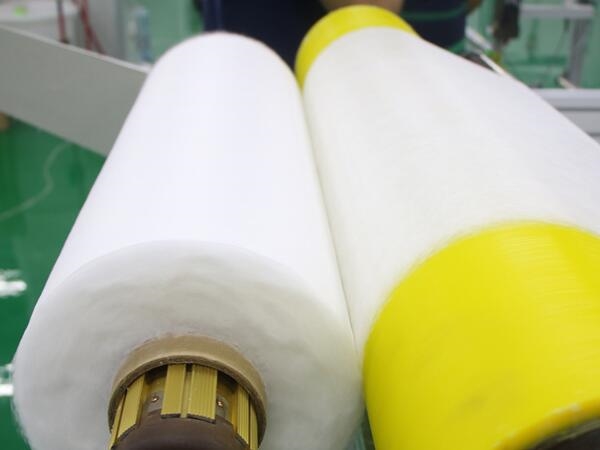

The melt blown fabric in production

The melt blown fabric in production

Electret treatment is to discharge a certain amount of charge on the melt blown fabric through high-voltage electrode discharge method. In this way, the melt blown fabric can attract particles by electrostatic action. The virus-bearing droplets will be blocked by criss-cross fibers first, and then be firmly attracted to the melt blown fabric by static electricity. After electret treatment, the filtering efficiency of the melt blown fabric will be greatly improved, which can reach more than 80%.

The usage of melt blown fabric

Melt blown fabric is widely used in many fields, such as air or liquid filter materials, mask materials, insulation materials, absorbent materials, thermal insulation materials, oil-absorbing materials, and wiping cloths. Especially in the field of mask making industry, melt blown fabric plays an irreplaceable role with its strong filtering performance.

Melt blown fabric is the core material in mask making industry

Melt blown fabric is the core material in mask making industry

As we all know, in the treatment and prevention of COVID-19 outbreak in 2020, medical masks, KN95 masks and N95 masks made of melt blown fabric, have played an important role in safeguarding the health of medical personnel and the people. Besides, in large, medium and small medical institutions, in the high season of SARS, avian influenza and H1N1 virus, different kinds of masks are all the necessary medical supplies.

The parameters of melt blown fabric

| Types | Parameters |

| Material | 100%polypropylene |

| Weight(GSM) | 25~35g |

| Production process | Hot melting+quickly spraying+electret treatment |

| Subfiltration efficiency(PFE),particle size:0.3μm | 95~99%(There are both single and double layers) |

| Filtration efficiency(BFE),particle size:0.5μm | 100% |

| Pressure drop(85LPM/) | Below 128Pa |

| Pressure drop(32LPM/) | Below 20Pa |

| Width of a reel of melt blown fabric | 1500mm, 600mm, 240mm |

| Length of a reel of melt blown fabric | 2500~2000m |

|

1.Test particle: paraffin oil 2.Can customize according to customer requirements, and provide third-party test report for each batch (more than 5 tons for a single batch) 3.Our factory has the qualification to produce medical melt blown fabric. |

|

The features of Doing Brand melt blown fabric

1. The diameter of fiber can reach 0.5~1 micron.

2. The appearance of melt blown fabric is white, smooth and soft.

3. After high voltage electret treatment, the melt blown fabric has the characteristics of low resistance, high efficiency and high dust holding capacity.

4. Specifications and sizes of melt blown fabric can be determined according to customer needs.

5. Direct supply from the manufacturer.